Marcus keeps us up to date with his progress at university.

This week he got some hands-on action!

To find out what he’s been working on, read his first post.

Re-designs and Testing

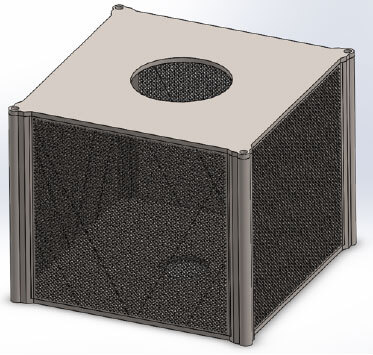

This week I had the chance to show my Faraday Cage design to my project supervisor. He liked the assembly concept, but suggested some improvements.

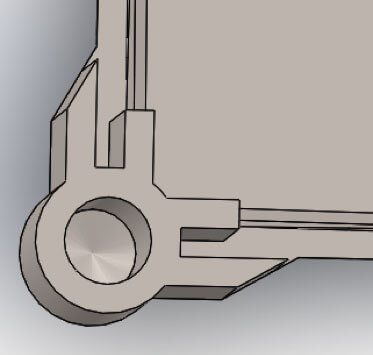

Firstly, in order to reduce the mass of the design, I’ve redesigned both the corner columns and the cage faces. The faces are now a lot thinner. However, they still need to be thick enough at each end to hold themselves in place at the columns. To achieve this we’ve made a cross-sectional design which begins thick, and tapers to a thinner cross-section for the main part of the face.

For the corner columns most of the unnecessary mass has been removed; leaving only the hole for the bolt, and the slots for the cage faces.

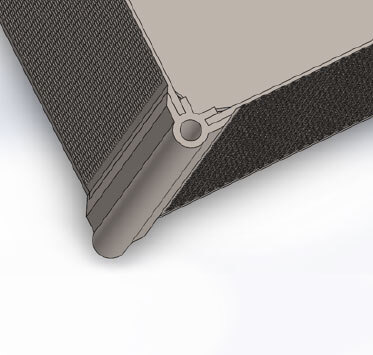

These slots are also tapered to produce a seamless geometry on the outside of the cage, as can be seen in this picture with the faces inserted:

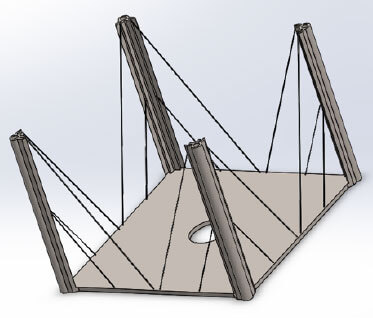

The other major change to the cage base is the inclusion of some support struts between the columns and the base. These are included to reduce any deformation of the cage, both during and after manufacture.

Here is what the whole structure will look like when it is put together:

This week, I have also been experimenting with PTFE, a type of plastic. We will use PTFE in our neutraliser for two purposes: One piece, a tube, will sit between the microwave antenna and the iron yoke. The rest of the PTFE will be used to insulate the sensitive neutraliser magnets from the high temperatures inside the neutraliser. I ordered a cylindrical rod of PTFE which I sawed into pieces for my tests.

Firstly, I wanted to test how easy it is to drill a hole in the PTFE rod, so that we could insert the antenna into it. I was able to drill a hole fairly easily, although I had to be careful to make sure I didn’t deform the plastic when clamping it in place!

My second test was to determine how easy PTFE is to bend. For the parts insulating the magnets, we would need to form a “C” shaped sleeve, as can be seen in the pictures. I used a heat gun to warm up the PTFE to a point where it could be bent. Once it had cooled down, the PTFE stayed in shape.

Next week, I will use a plastic bending machine with a PTFE sheet (rather than a rod) to try and do this more accurately.

Marcus Collier-Wright